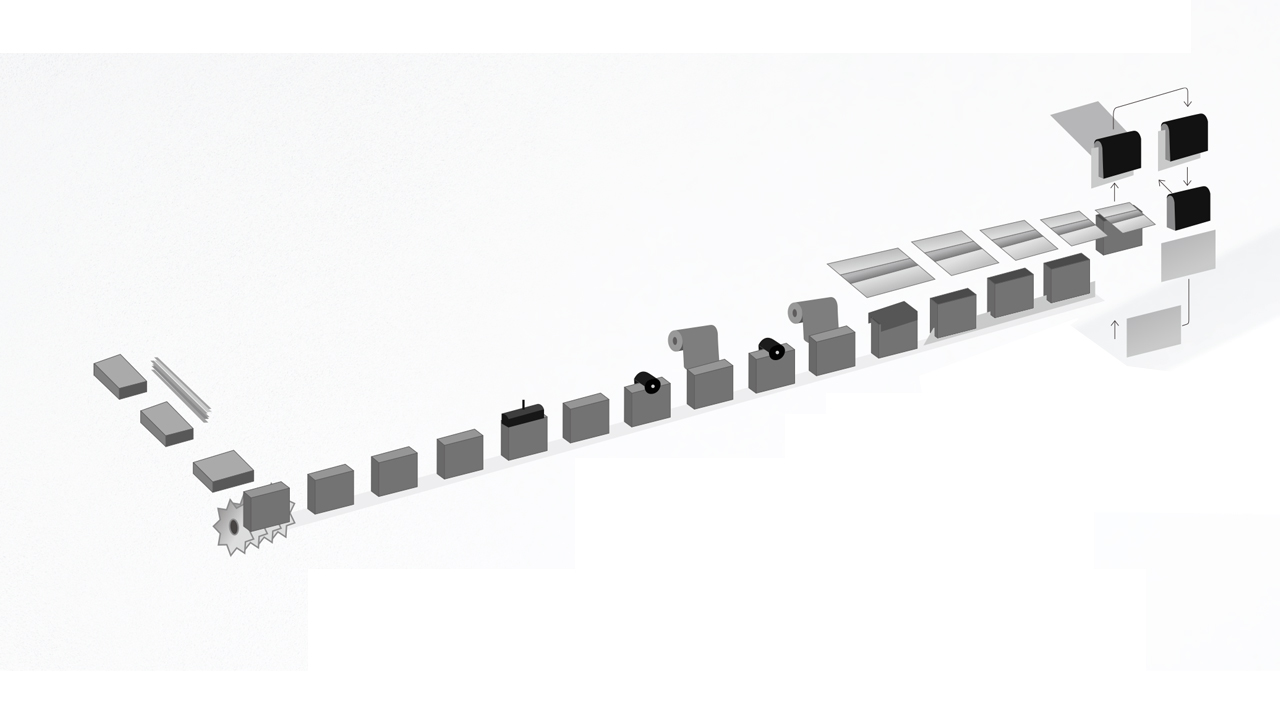

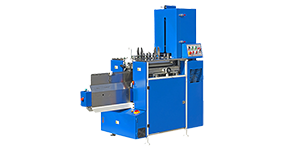

HX Classic 680 Automatic High Speed Hardcover Book Production Line is the first high-speed hardcover book production line in China, with the intelligent human-machinery touch-screen control panel, the book block is rounded in the rounding station with rollers, then the book block joint area is laterally backed in the backing station by backing jaws A forming iron gives the book spine its desired form and width. In the correction station, the book block is raised to through feed height and aligned to the back cut. Spine gluing with hot glue, gauzing, backlining, and headbanding take place during the timed transport. A rub-down station (Teflon band) with an additionally integrated foam rubber rub-down element, adapted to the book radius, presses the backlining material onto the full surface of the block spine. For casing in, the book block is pushed onto the splitter sword and taken over by the transport wings of a paternoster system. Subsequently, the joint and end sheets are glued on both book block sides. The glued book block is guided into the aligned bookcase using the transport wings. The book block and case are pressed together in the book clamp. Then the cased in book is conveyed from the paternoster to the delivery. With the optional hardcover book interleaving piler, hardcover books can be counted and interleaving stacking, then by the manipulator, palletizing the book stack automatically.

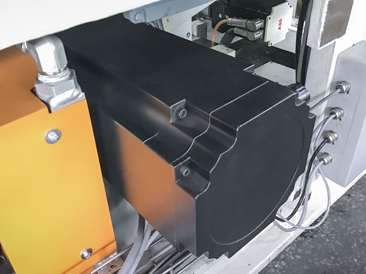

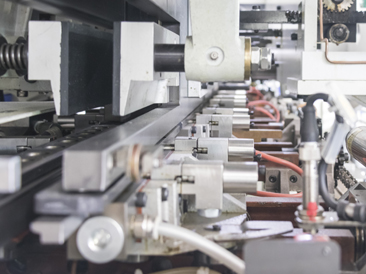

Book Back Rounding Station

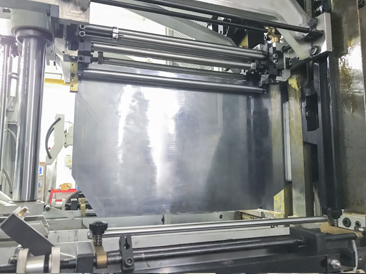

Book Back Rounding Station Prepressing Casing In

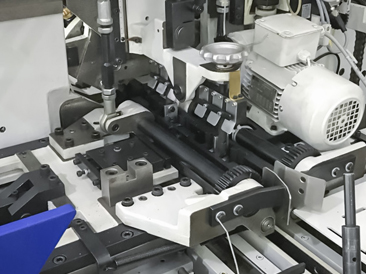

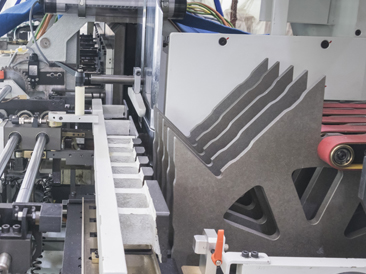

Prepressing Casing In Casing In Splitter Sword

Casing In Splitter Sword Cold Glue Roller

Cold Glue Roller ABB Servo System

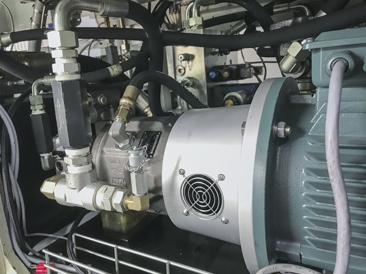

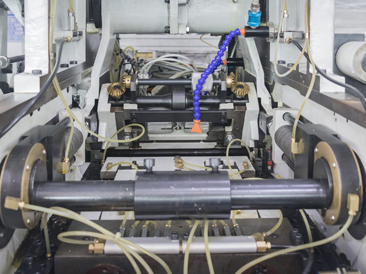

ABB Servo System Oil Pressure System

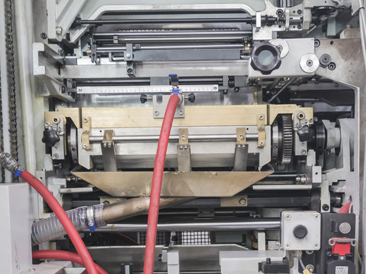

Oil Pressure System Headbanding Station

Headbanding Station 6 sets of Oil Pressure Board System

6 sets of Oil Pressure Board System Hotmelt Glue Premelting Container

Hotmelt Glue Premelting Container SKF Automatic lubricating system

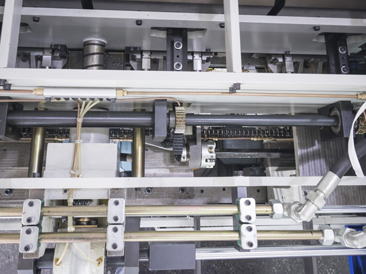

SKF Automatic lubricating system 6 sets of Preheat Grooving Clip System

6 sets of Preheat Grooving Clip System Oil Pressure Infeed

Oil Pressure Infeed Book Backing and Correction Station

Book Backing and Correction Station Hardcover Case Feeder

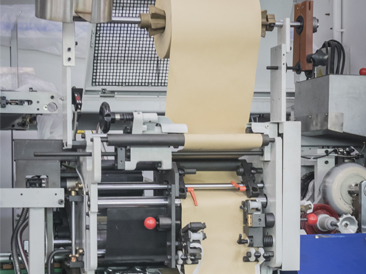

Hardcover Case Feeder Gauze Station

Gauze Station Electrical Compartment

Electrical Compartment Touch Screen Control Panel

Touch Screen Control Panel